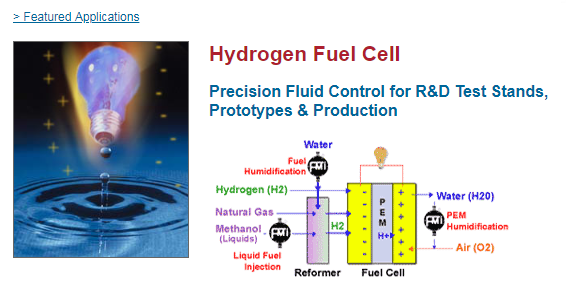

Featured Applications - Hydrogen Fuel Cell

Fluid Metering’s valveless piston pump has been chosen to perform critical fluid control functions of the fuel cell and reformer operations including:

- Precision addition of DI water into both liquid and gaseous fuels.

- Recirculating the pure water created as a by-product of the reaction into the oxygen source (air). Accuracy and reliability of the humidification of this function is important to the operation and efficiency of the fuel cell).

- Liquid Fuel Metering (typically Methanol or a Methanol / DI water mix) into the reformer

- DI water addition into the steam reformer.

R&D and Prototyping

For R&D and prototyping, FMI QV and RHV Variable Speed Pumps provide extreme flexibility of flow range and process control capability. These pumps feature both mechanical stroke volume adjustment and pump speed adjustment via the versatile V300 Stroke Rate Controller. The V300 is easily integrated into process control devices (sensors, computers, PLC’s) via a 4-20mA interface. Send Us Your Application Specs Production

STH,STQ and SQ Pumps integrate FMI’s patented valveless CeramPump® with precision long life stepper motors in a compact design. These pumps are ideal for production fuel cell stacks and steam reformers used for remote and residential installations requiring maintenance-free operation.

Hydrogen Fuel Cell Basics

Unlike most conventional methods of generating electric energy which develop power through combustion, the Hydrogen Fuel Cell generates electric power through an electro-chemical process. The process is extremely efficient and virtually emission free.

Fuel cells are similar to batteries in that they convert chemical energy into electricity. Without any moving parts both require minimum maintenance. However, unlike the battery, the Hydrogen Fuel Cell does not have to be recharged since the regeneration process is ongoing.

The anode and cathode sections of the fuel cell are separated by a Polymer Electrolyte Membrane (also termed a proton exchange membrane or PEM). The electrical potential across the membrane is maintained through the continuous addition of hydrogen rich fuel and the fact that the proton exchange membrane (PEM) allows only hydrogen +ions (protons) to pass from the anode to the cathode side. The result is a one way migration of protons across the membrane creating a continuous “charged” state. A by-product of the reaction is pure water, created by the combining of oxygen and hydrogen (H2O) also serves as the source of water used in the humidification of the proton exchange membrane.

Water Management and Fuel Cell Performance

Polymer electrolyte membranes are somewhat unusual electrolytes in that, in the presence of water, which the membrane readily absorbs, the negative ions are rigidly held within their structure. Therefore, Water Management is the key to efficient operation of the fuel cell. Although water is a product of the fuel cell reaction and is carried out of the cell during its operation, it is essential that both the fuel (hydrogen source) and air (oxygen source) entering the fuel cell be humidified. Too little water prevents the membrane from conducting the H+ ions well and the cell current drops. Keeping the PEM hydrated requires precision metering of water into the fuel and air entering the cell membrane.